Page 20 - machining_titanium_05_2019

P. 20

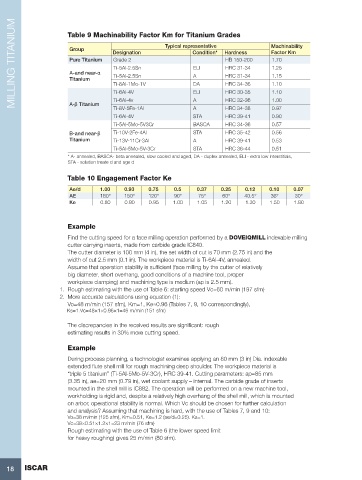

MILLING TITANIUM Table 9 Machinability Factor Km for Titanium Grades Machinability

Typical representative

Group

Factor Km

Hardness

Designation

Condition*

HB 150-200

Pure Titanium

1.70

Grade 2

ELI

HRC 31-34

1.25

Ti-5Al-2.5Sn

Α-and near-α

A

HRC 31-34

Ti-5Al-2.5Sn

1.15

Titanium

Ti-8Al-1Mo-1V

HRC 34-36

1.10

DA

Ti-6Al-4V

A

1.00

HRC 32-36

Ti-6Al-4v

Α-β Titanium

HRC 34-38

A

Ti-8V-5Fe-1Al

0.97

0.90

Ti-6Al-4V ELI HRC 30-35 1.10

STA

HRC 39-41

Ti-5Al-5Mo-5V3Cr BASCA HRC 34-36 0.57

Β-and near-β Ti-10V-2Fe-4Al STA HRC 35-42 0.56

Titanium Ti-13V-11Cr-3Al A HRC 39-41 0.53

Ti-5Al-5Mo-5V-3Cr STA HRC 36-44 0.51

* A- annealed, BASCA- beta annealed, slow cooled and aged, DA - duplex annealed, ELI - extra low interstitials,

STA - solution treate d and age d

Table 10 Engagement Factor Ke

Ae/d 1.00 0.93 0.75 0.5 0.37 0.25 0.12 0.10 0.07

AE 180° 150° 120° 90° 75° 60° 40.5° 36° 30°

Ke 0.80 0.90 0.95 1.00 1.05 1.20 1.30 1.50 1.80

Example

Find the cutting speed for a face milling operation performed by a DOVEIQMILL indexable milling

cutter carrying inserts, made from carbide grade IC840.

The cutter diameter is 100 mm (4 in), the set width of cut is 70 mm (2.75 in) and the

width of cut 2.5 mm (0.1 in). The workpiece material is Ti-6Al-4V, annealed.

Assume that operation stability is sufficient (face milling by the cutter of relatively

big diameter, short overhang, good conditions of a machine tool, proper

workpiece clamping) and machining type is medium (ap is 2.5 mm).

1. Rough estimating with the use of Table 6: starting speed Vc=60 m/min (197 sfm)

2. More accurate calculations using equation (1):

Vo=48 m/min (157 sfm), Km=1, Ke≈0.96 (Tables 7, 9, 10 correspondingly),

Ks=1.Vc=48×1×0.96×1=46 m/min (151 sfm)

The discrepancies in the received results are significant: rough

estimating results in 30% more cutting speed.

Example

During process planning, a technologist examines applying an 80 mm (3 in) Dia. indexable

extended flute shell mill for rough machining deep shoulder. The workpiece material is

“triple 5 titanium” (Ti-5Al-5Mo-5V-3Cr), HRC 39-41. Cutting parameters: ap=85 mm

(3.35 in), ae=20 mm (0.79 in), wet coolant supply – internal. The carbide grade of inserts

mounted in the shell mill is IC882. The operation will be performed on a new machine tool,

workholding is rigid and, despite a relatively high overhang of the shell mill, which is mounted

on arbor, operational stability is normal. Which Vc should be chosen for further calculation

and analysis? Assuming that machining is hard, with the use of Tables 7, 9 and 10:

Vo=38 m/min (125 sfm), Km=0.51, Ke=1.2 (ae/d=0.25). Ks=1.

Vc=38×0.51×1.2×1=23 m/min (76 sfm)

Rough estimating with the use of Table 6 (the lower speed limit

for heavy roughing) gives 25 m/min (80 sfm).

18 ISCAR