Page 9 - TURNING CATALOG p121-254

P. 9

Chipformers USER GUIDE ISOTURN INSERTS

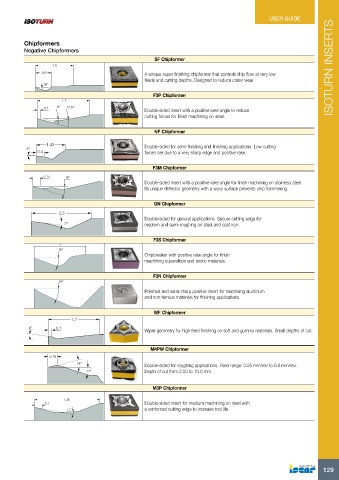

Negative Chipformers

SF Chipformer

1.5 A unique super finishing chipformer that controls chip flow at very low

0.6 feeds and cutting depths. Designed to reduce crater wear.

18˚

F3P Chipformer

1.7

0.1 6° 12.5° Double-sided insert with a positive rake angle to reduce

cutting forces for finish machining on steel.

1.42

4º 0.4 NF Chipformer

Double-sided for semi-finishing and finishing applications. Low cutting

0.15 15° forces are due to a very sharp edge and positive rake.

1 F3M Chipformer

20° Double-sided insert with a positive rake angle for finish machining on stainless steel.

Its unique deflector geometry with a wavy surface prevents chip hammering.

24°

GN Chipformer

1.7 Double-sided for general applications. Secure cutting edge for

8˚ 0.1 medium and semi-roughing on steel and cast iron.

0.19 F3S Chipformer

14º Chipbreaker with positive rake angle for finish

machining superalloys and exotic materials.

17º

F3N Chipformer

1.35

0.1 Polished and extra sharp positive insert for machining aluminum

and non-ferrous materials for finishing applications.

11°

WF Chipformer

Wiper geometry for high feed finishing on soft and gummy materials. Small depths of cut.

M4PW Chipformer

Double-sided for roughing applications. Feed range: 0.25 mm/rev to 0.8 mm/rev.

Depth of cut from 2.00 to 10.0 mm.

M3P Chipformer

Double-sided insert for medium machining on steel with

a reinforced cutting edge to increase tool life.

129